E-Beam Evaporating System

E-Beam Systems

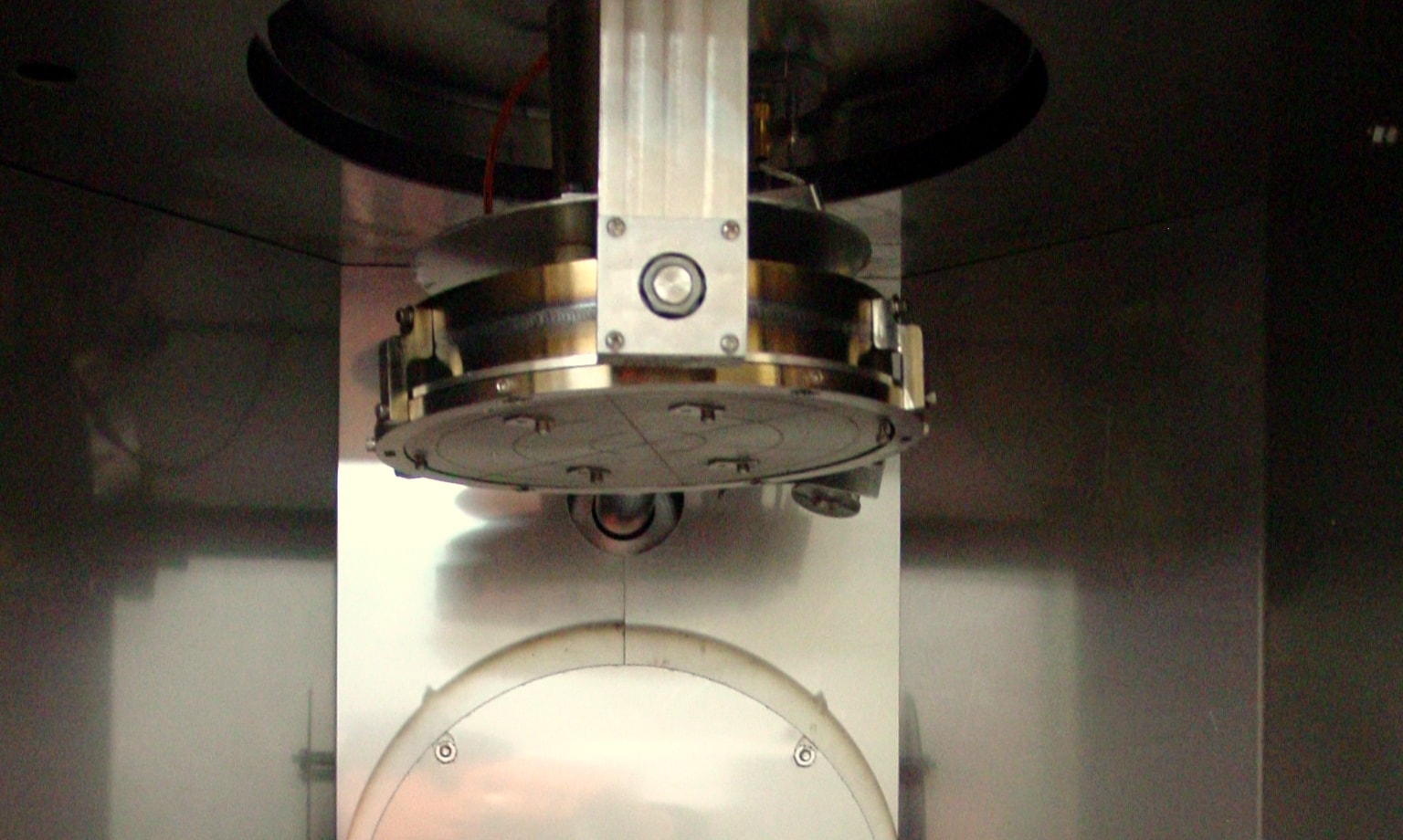

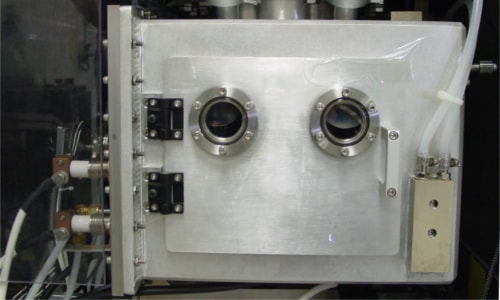

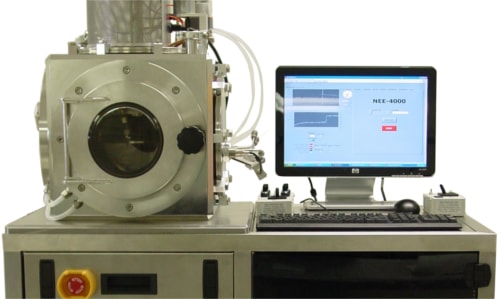

The Electron Beam Evaporation System is available in two different configurations. A compact vertical dual chamber configuration features a 14" cube main chamber where the platen is located, and underneath the main chamber a secondary chamber is provided for housing the e-beam source. This configuration can be provided with a gate valve between the two chambers to be used as a load lock to keep the e-beam source and the evaporation pockets in vacuum while substrates are loaded and unloaded from the main chamber. For applications where automatic loading and unloading of wafers are needed, a third load lock chamber is attached to the left face of the cube for another load lock. In this case, the main chamber can be kept at low 10-7 Torr range at all times and evaporation can start just a few minutes after loading the wafer. The second configuration features a single large chamber design that allows e-beam evaporation guns, magnetrons, and thermal evaporation mounted onto the baseplate. In this configuration coating of mulitple wafers are possible using planetary substrate holder.

NANO-MASTER offers combinatorial evaporation system using substrate masking and computer controlled evaporation rates for individual e-beam evaporators

- Electropolished 14” cubical or 21”x21”x22” 304L SS chamber

- 5x10-7 Torr base pressure attained with turbomolecular pumping package

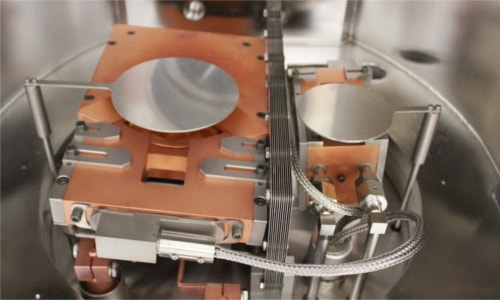

- 4x 15cc pocket E-gun

- Source and substrate shutters

- 6kW and 10kW switching power supply

- Automatic pocket indexing

- Programmable sweep controller

- 26” x 44” footprint with SS panels for Class 100 cleanrooms

- Quartz crystal thickness sensor

- Substrate rotation

- LabVIEW user interface

- EMO protection and safety interlocks

- Substrate heating up to 800°C or cooling

- Glancing Angle Deposition (GLAD) with rotation

- Planetary substrate holder

- Substrate RF/DC bias

- Dual e-beam source for co-evaporation

- Ion source for substrate cleaning and ion assisted evaporation

- Additional PVD sources (thermal, sputtering)

- MFC’s for reactive evaporation

- Automatic load/unload

- Lift Off

- Optical Coatings

- Thin Film Transistors

- Active CIGS layer

- Josephson Junctions