Single Wafer Cleaning

Single Wafer Cleaning Systems

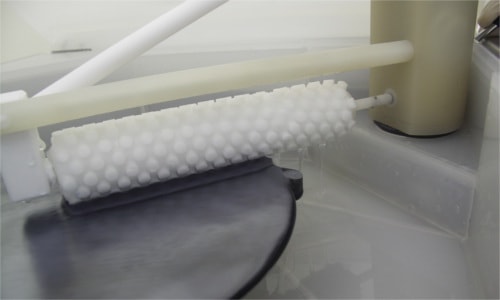

NANO-MASTERS’s Single Wafer Cleaners (SWC) focus on providing the best possible cleaning capability while maintaining affordability. A standard system is configured with clean, chemical clean, brush clean, high RPM spin dry with IR heating and N2 flow. Patented megasonic nozzle movement assures uniform delivery of megasonic energy; therefore, at any point on the surface, energy delivered can be kept below damage threshold.

- 12" OD, 7" x 7" substrates

- Table top unit

- Venturi powered vacuum

- Damage free megasonic

- Independent chemical dispenses

- Spin dry with heated N2

- Microprocessor controlled

- Chemical dispense unit

- Safety interlocks

- 19”x26” footprint

- PVA brush cleaning (100 RPM)

- Post CMP brush cleaning (up to 400 RPM)

- Nitrogen ionizer

- CO2 inject with DIW resistivity monitor

- FM4910 Materials

- Four 3.8L HDPE canisters

- Stand alone unit

- Dual drain for acids and solvents

- Suck back valves to prevent drips

- Back side DIW clean and dry

- In-line heaters for DIW or chemicals

- Fill sensors for chemical or DIW leaks

- Patterned and unpatterned masks and wafers

- Ge, GaAs and InP wafer cleaning

- Post CMP wafer cleaning

- Cleaning of diced chips on wafer frame

- Cleaning after plasma etch or photoresist stripping

- Mask blanks or contact mask cleaning

- Cleaning of X-ray and EUV masks

- Optical lens cleaning

- Cleaning of ITO coated display panels

- Megasonic assisted lift-off process